Slow Drying

FOR HIGH–QUALITY PASTA

Drying has always been considered the crucial and most demanding stage in the pasta production process, determining the quality of the pasta. This is why De Cecco continues to opt for low-temperature slow drying, adopting the same principles as its founder Filippo De Cecco, who according to the Treccani Encyclopaedia was the inventor of this revolutionary warm-air drying system in 1889. Findings from recent studies on pastas available on the market have highlighted that De Cecco’s durum wheat semolina pasta does not exhibit the effects of high temperature that cause a drop in quality and nutritional properties. Low-temperature slow drying allows for flavours to develop that give the characteristic taste to the pasta and the typical yellow of the semolina, guaranteeing the utmost firmness when cooking: given this, De Cecco pasta can be considered of HIGH QUALITY. The sticker found on the packaging is the result of hours of drying certified by DNV, that, depending on the pasta type, must be from 9 hours for short pasta, to 18 hours for long pasta, and up to 36 hours for the lunghi bucati long shapes. De Cecco, wishing to provide transparent information, feels that letting consumers know about this decisive factor will help them to make an informed choice...

download the pdf

Product Certification

(STP-ce-pcagro 38)

De Cecco is the first producer of pasta in Italy that has received the product certification (issued by the DNV society, one of the most influential certifying institutions in the world) implementing the development that started some years ago with the adoption of the quality system ISO 9001:2000.

This certification, by means of analyses and monitoring performed by an independent third-party institution, attests that the product conforms to the characteristics of excellence declared by the certified subject. The adoption of this standard allows these organoleptic and nutritional qualities to be visible. The certified parameters are constantly measured.

With regard to this, product specifications quote that:

“De Cecco is one of the few industrial pasta industries that, rather than increasing the quantity of products made, aims at preserving the quality of this product. And it is not generic "quality", which cannot be rendered better to the consumer, but quality based on practical data, on analytical parameters that are already object of constant measuring and monitoring.

This is why De Cecco decided to certify the parameters of quality of its products: because without guarantees, you cannot have concreteness either; and without concreteness you cannot have true quality.”

download the pdf

De Cecco wholegrain pasta and the University of Milan

In addition to the ongoing and in-depth quality controls at its own laboratories, De Cecco decided to ascertain the quality of its pasta with one of the most prestigious external authorities, the University of Milan - Department of Food, Environmental and Nutritional Sciences (DeFENS). The company commissioned a research study to define some qualitative aspects of wholegrain durum wheat semolina pasta. The study was carried out on samples from ten pasta brands, representing around 80% of the Italian wholegrain pasta market. The research project took place in 2015 and 2017. In 2019, the tests were repeated using the indicators for heat damage (furosine and pyrraline) on the same pasta brands, essentially confirming the previous results. We have outlined some of the key points of the research study to clearly and precisely inform consumers.

download the pdf

EPD Certification

The Environmental Product Declaration (EPD) is a certification which objectively quantifies, according to internationally recognized scientific methods, the overall environmental impact of the production, marketing and consumption of a good or service. The EPD is based on Life Cycle Assessment (LCA) methodology, which takes into account all consumption of natural resources (water, energy, raw materials) and all releases into the environment (from CO2 though to waste) which occur, right from the cultivation stage through to the relevant packaging materials going to landfill. The LCA model also calculates the contribution of the product's life cycle to the main phenomena changing our environment, such as global warming, acid rain and water pollution. The EPD is a certification approved by an entity which is independent of the company (Environdec) with a review process that ensures the accuracy and validity of the data and calculation methods used.

Holding an Environmental Product Declaration demonstrates a willingness to communicate – objectively, transparently and fully – the environmental impact of a business and the phenomena connected to it. The EPD permits the assessment of these impacts not only in absolute terms, but also by way of comparison between products and services from the same category (e.g. pasta, etc...) or from different supply and consumption chains. In this way, consumers and trade buyers can evaluate the comparative environmental impacts of their purchasing decisions. Finally, a completed EPD allows the company to have all the relevant and meaningful information at hand in order to put schemes in place to minimise the environmental impacts of its products.

download the pdf

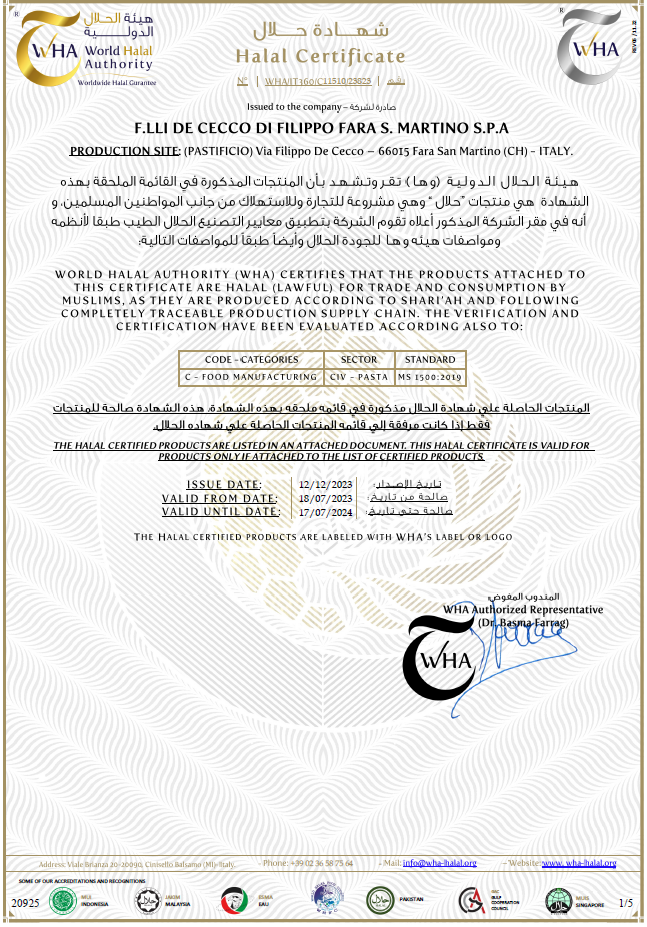

Halal Certification

Halal International Authority (HIA) certifies that the products are lawful for trade and consuption by muslims, as they are produced according to Sharia’ah and following completely traceable production supply chain.

The word “HALAL” means “lawful” and refers to every actions a muslim can do and to every food a muslim can eat as compliant to the law.

Plants in Fara San Martino (pasta and extra virgin olive oil factory) and Ortona (pasta factory) produce goods certified by Halal since 15/07/2015.

download the pdf

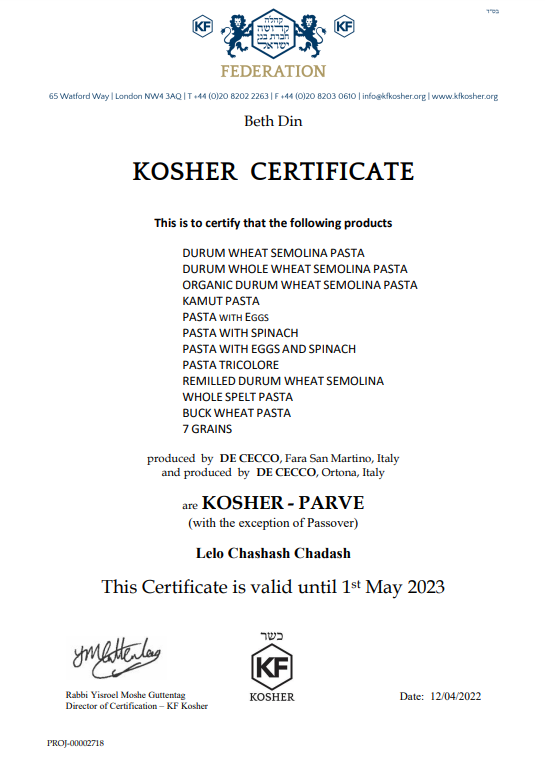

Certification Kosher

This certification has been adopted following the requests of the Jewish community.

It indicates the suitability of a product to be consumed by Jews, in concordance with the dietary rules of the Jewish religion.

download the pdf

International Food Standard

IFS

This is a specific standard for the food sector that takes form as an operational instrument aimed at qualifying its suppliers according to requirements of quality, safety and conformity to the regulations on food products.

The approach is similar to the one adopted by the BRC and consists of an elaboration of the issues dealt with by the HACCP system, addressing particular attention towards hygiene and sanitary requirements, the guarantee of product quality, the formulation of a number of preventive measures and controls that are also confirmed by a system of accredited laboratories.

download the pdf

British Retail Consortium

The BRC standard (developed in England in 1998 by the British Retail Consortium) concerns the hygiene and food safety of agricultural food products and in particular:

1) Structural specifications for productive environments;

2) Product and process specifications;

3) Behavioural standards for personnel and visitors;

4) Hygiene standards for personnel and visitors;

5) The absence of allergens for consumers at risk;

6) The absence of genetically modified organisms;

7) The traceability of the raw materials used and of the finished product.

download the pdf

HACCP

(Hygiene and Food Self-monitoring System - UNI 10854)

The HACCP certification is a self-monitoring system implemented by De Cecco to monitor the whole production and distribution chain of the product in order to guarantee its healthiness for the final consumer.

download the pdf

ISO 9001:2015

(Quality Management System)

Quality Management System that covers the correct structuring of company processes aimed at guaranteeing the continual improvement of performance, in order to maintain the constant quality of products and services offered to Clients/Consumers.

For this purpose, a number of internal procedures are elaborated, representing the main method to discipline the processes identified in advance.

download the pdf

Certification SA8000

Policy for Social Responsibility

For more than a century De Cecco has been scrupulous in selecting raw materials, in producing a high-quality product, in valorising human resources that work for De Cecco and towards the client as the main interlocutor.

Our competitive strength is founded on these mainstays and with this policy we have become, and we intend to remain, protagonists on the market and leading strength in the social fabric.

For this reason we have decided to strengthen and spread the vision that originates from our philosophy: a value system based on the search for balance between profitability and sociality, created from the combination of the company results with the principles relative to Social Responsibility through the adoption of the SA8000 standard and the motivation to improve that the latter generates within the organization and outside it in the process of selection and evaluation of suppliers.

The choice to adhere to the standard for Social Responsibility SA8000 is the confirmation of our industrial and financial strategies and of our operational conduct always oriented to the benefit of all those who with commitment contribute to the realization of our projects and to the creation of value.

For this reason, to integrate the policy for Quality, we have formalized the document of our Policy for Social Responsibility.

Our history proves that everything is possible and that we will be able to achieve new goals thanks to our conduct:

- considering employees as a strategic resource, by guaranteeing the respect of their rights and promoting their professional and personal development

- considering suppliers as partners that have to be valorised, in terms of quality and of development with respect to social responsibility;

- considering clients and consumers as protagonists in the success of De Cecco and its growth, always working to satisfy their requirements from a qualitative point of view, and from now onwards, we will also try to meet any requests that emerge concerning social responsibility.

download the pdf

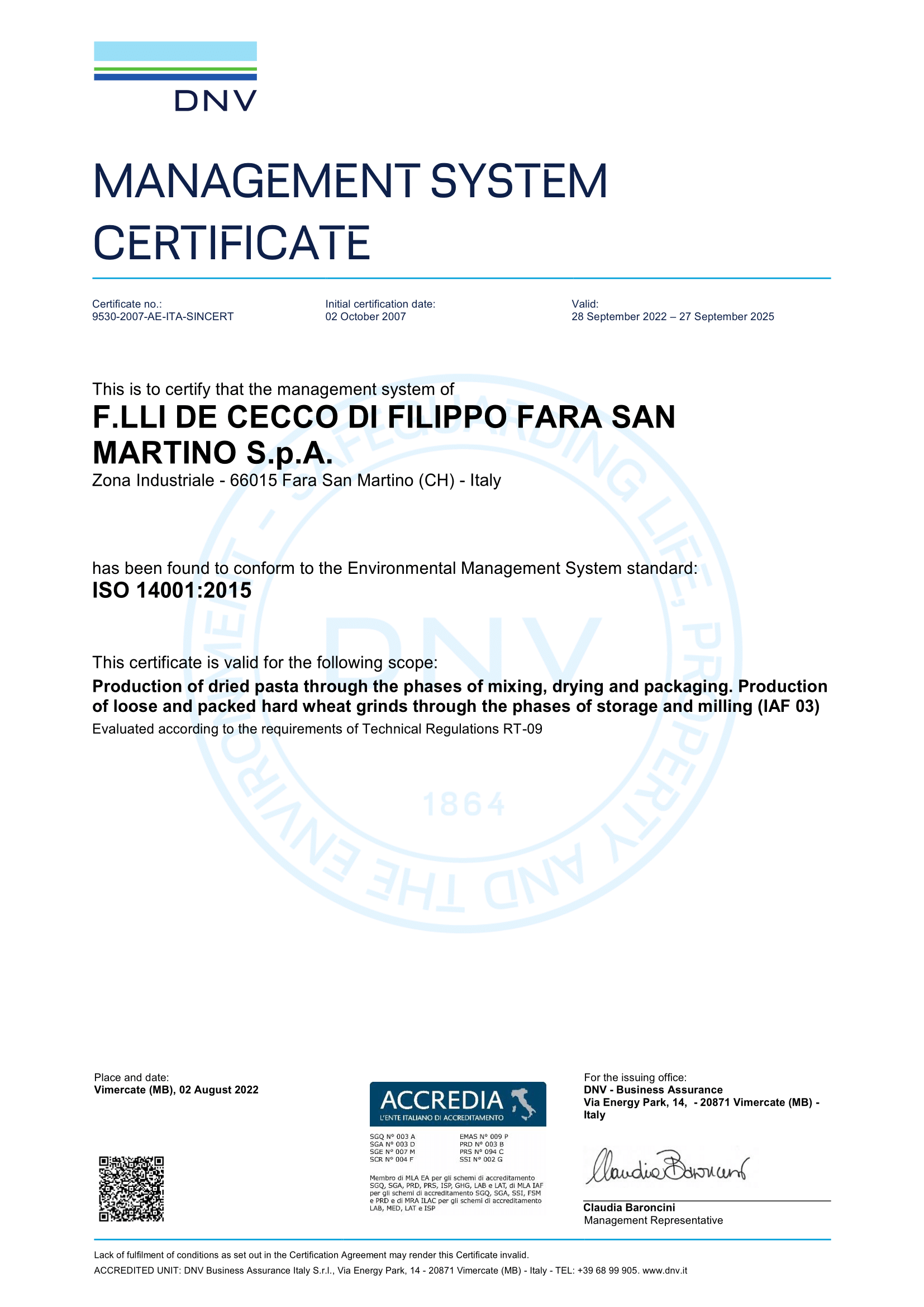

Environmental Certification

( ISO 14001: 2015)

The environmental certification is a voluntary instrument for self-monitoring and assumption of responsibility aimed at pursuing the continual improvement of environmental performances.

It is a System that allows to identify and contextually safeguard all significant environmental aspects and therefore guarantee the total respect of the latter.

Always scrupulous in safeguarding the ecosystem in which its productive activities are carried out, the De Cecco has decided to develop an Environmental Management System in conformity with the ISO 14001:2015 standard.

With this system it intends to:

- guarantee conformity with environmental regulations and its continual improvement of environmental performances

- monitor with continuity its environmental performances

- plan and carry through the improvement of such performances, reducing the environmental impact

- prevent possible environmental damage.

download the pdf