{{currentSection }}

di

{{totalSections - 1 }}

{{ currentChapter }}

Go to the Section

Our Method

Doing things right is a question of Method.

Since 1886, we’ve been committed to bringing the authentic pleasure of Italian cuisine to tables throughout the world, with great responsibility and without compromise. We are the keepers of an ancient tradition characterised by passion for our work and attention to every single detail. It’s our way of doing things well: #AllaDeCecco.

explore our method

Where the Method originated

Ours is a story of passion, tradition and determination, characteristics typical of the Abruzzi territory. Our production facilities in Fara San Martino have forever been nestled between the majestic mountains of Majella. This is where the De Cecco working Method was born, unique to its kind, just like these locations.

Photo © Francesco Ventriglia Campana

Selecting the wheat

Only the best durum wheat

We select the best durum wheat from Italy, California and Arizona because the characteristics of excellence cannot be found in just one variety of wheat.

In fact, we choose Italian wheat for its flavour, and California and Arizona wheat for the quantity and quality of the proteins which make the pasta “al dente”, firm and elastic, therefore, unique in its kind.

This is one of the characteristics which distinguish our pasta from any other pasta.

Selecting the wheat

Quality is a shade of amber

Our experts select the primary materials by touching the quality of durum wheat first-hand. They do so before the harvest is collected, while its still in the fields, before being sent to the Fara San Martino Mill. Because quality is perceived in the blink of an eye, in the shade of amber and the fullness of the grains.

Selecting the wheat

Wholesomeness first of all

After having been selected in the fields, the wheat must pass our laboratories’ strict controls: we look for perfect wholesomeness and our wheat must be in line with the highest qualitative standards.

The De Cecco parameters are even more severe than those provided for by legislation; the wheat we use is rigorously controlled at the origin, upon arrival and during production by our agronomists.

The laboratory technicians verify the purity, the appearance and all of the physical and chemical characteristics of the grains.

Selecting the wheat

A combination of science and experience

To eliminate all doubt, in addition to the numerous analyses, we also add the experience of an ancient ritual: a final bare-handed gluten test, through the owners’ expert touch, to check the tenacity and elasticity of the primary product. The different wheat varieties will now be mixed to create the perfect balance of flavour, colour and perfumes, typical of our pasta.

Milling

We grind the wheat in our mill

We have been millers for almost two centuries, since back in 1831 when Don Nicola De Cecco produced “the best flour in the county” in his stone mill in Fara San Martino. And we are proud to have kept this tradition alive. To guarantee fresh semolina all the time, we grind the wheat in our own mill, right next to the pasta factory, floating with intense and delicious aromas.

Milling

Quality, not quantity

During the milling process, the grains of wheat are “stripped” of their surface layer until reaching the central, most valuable part. And it is this very strategy of getting “straight to the heart” that explains our low grinding output: 100 kg of wheat per day to obtain about 65 kg of semolina, instead of a possible 80 kg. Only using this approach are we able to develop a truly #AllaDeCecco pasta.

Milling

“Coarse” grain semolina

So as not to damage the grains, our grinding process produces semolina having a larger particle size compared to that normally used to produce pasta. Coarse grain semolina is difficult to process: it takes longer to be completely hydrated by water.

Dough

Only fresh water from our own spring

Pure, cold mountain water is constantly flowing under the pasta factory, from the De Cecco® Spring, which flows right into our facilities. At Fara San Martino we knead the semolina using this water alone, at a temperature of less than 15°C. This slow working method better respects the primary material, preserving the integrity of the precious gluten network.

PLAY VIDEO

The De Cecco spring

FARA SAN MARTINO - ITALY

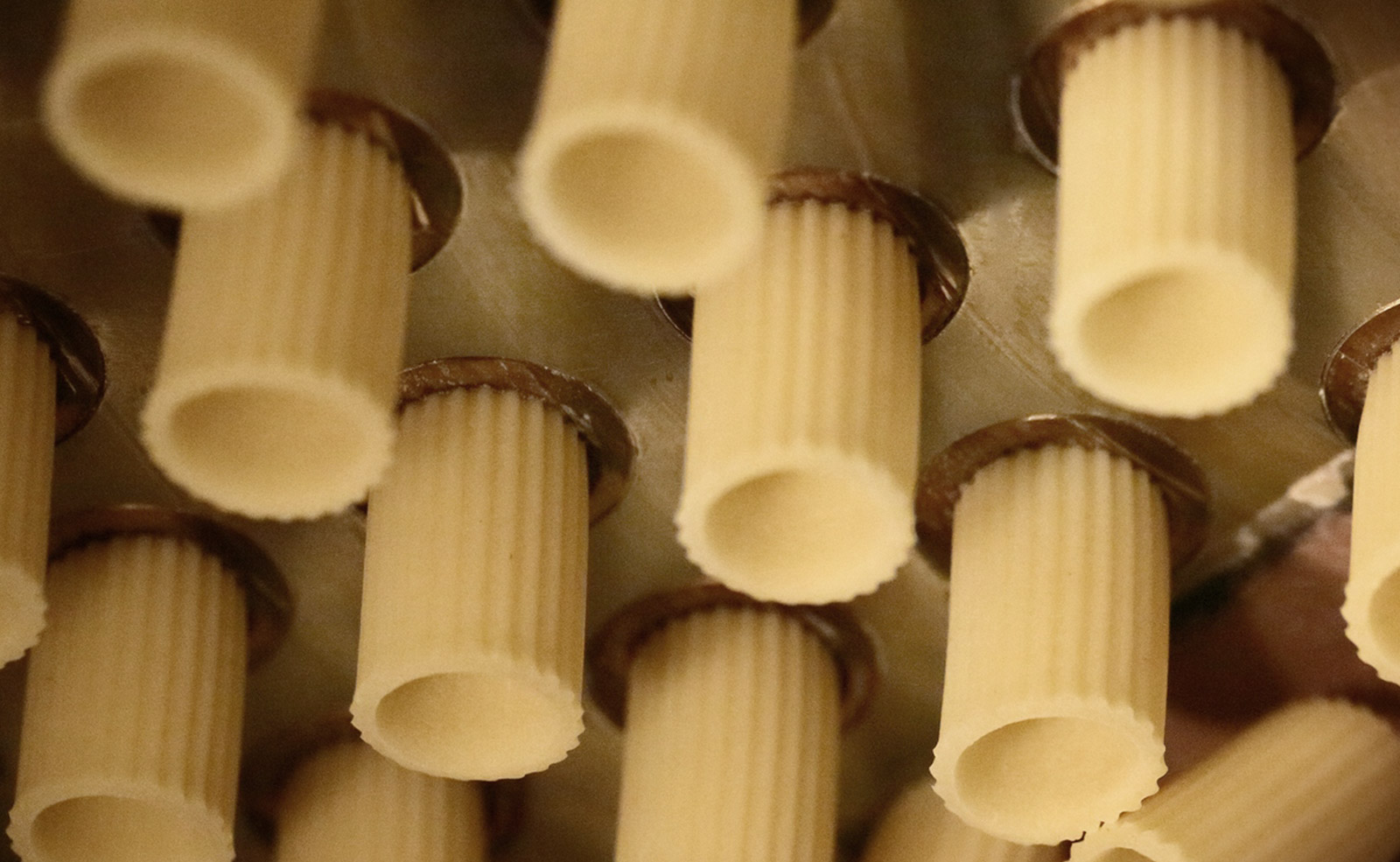

Drawing

Or rather, the importance of never abandoning a tradition

If you run your finger over a De Cecco Penna or Spaghetto, you will notice that the pasta has a slightly rough feel, the result of the rough extrusion. Although technological progress has offered faster and cheaper solutions, we have continued to use bronze draw-plates and to defend this processing method. Because it’s the only one that makes the pasta naturally rough, porous and able to absorb every type of sauce.

Drying

Innovation has our name on it

Pasta was traditionally dried under the sun, thus exposing it to variable temperatures in poor hygienic conditions. It was Filippo Giovanni De Cecco, back in 1889, who perfected the first warm-air drying plant. An innovation of historical importance, which earned the founder of De Cecco a place in the Treccani Encyclopaedia.

Drying

Low temperature and slow

This is who how we keep the sensory properties of the wheat intact and enhance the nutritional qualities of our pasta. To the point where some formats take 40 hours to dry.